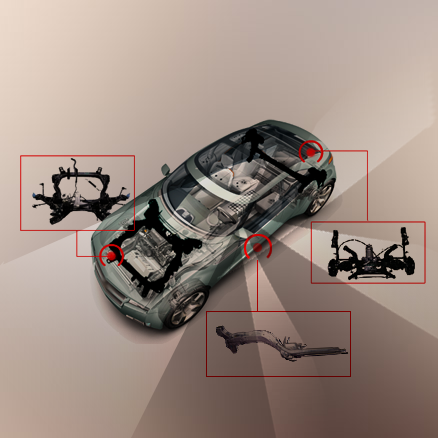

AUSTEM Assembly Plants

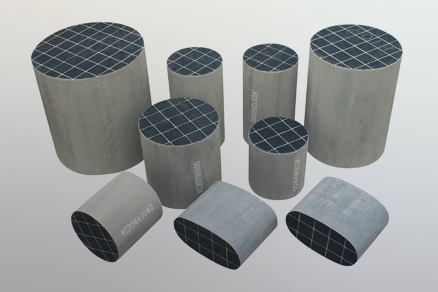

Austem, is a global corporation, based in Korea, and besides 6 assembly plants in Korea, we have established 4 assembly plants in China, a plant in Pune, India, and a plant in Uzbekistan (strategically located to open up future business in central Europe and beyond). In 2010, Austem reached an agreement to purchase IB Materials, formerly a part of LG’s Chemical DPF division. IB Materials is now part of the Austem family creating a synergic effect on energy reduction and the eco-friendly ceramic material business.