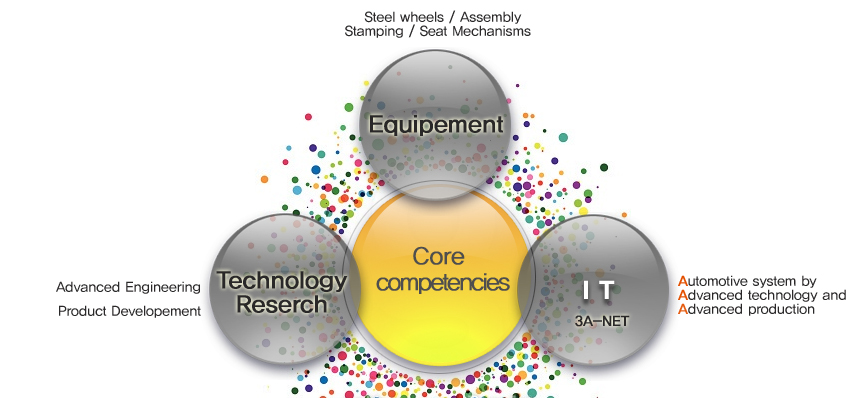

Core competencies

Advanced Engineering / Design & Analysis/ Total Engineering Service

ㆍSteel Wheel

ㆍStyled Wheel, Skeleton Wheel

ㆍFront / Rear Suspension, Modular Engineering

Products Design/Die Design/Process Design

ㆍBody parts

ㆍSuspension Parts

ㆍSteel wheel

Total Engineering Service System for customer satisfaction and excitement by building an integrated working process based on the accumulated experience of Design, Analysis, testing and component development

Design System flow

Austem specializes in the design and development of new product segments and of underdeveloped product segments, such as New Style Steel Wheels.

Austem spent 3 years developing Hydroforming and was the first company in Korea to implement this manufacturing process. Unlike the press compression-molding, hydroforming uses fluid to form complex and intricate shapes of high quality and stability.

Smart Wheel Development of composite parts for passenger cars developed applying the hybrid-material

technology Hydroforming.

Smart Wheel Development involves the use of multiple manufacturing techniques, and materials including

hydroformed parts in combination with composite materials.

Automotive steering, suspension control module 3-axis fatigue testing machine development. Many patent

applications have been filed for the Proto Develop System flow.

High strength, high ductility steel, is being used to minimize the weight of the rear suspension links. Further light weighting initiatives involve the development of an aluminum billet material process (2010-2013) to produce light weight automotive parts of high strength and durability.

Development of Aluminum parts for electric cars, including Front Cradles, Rear Axles, Knuckles etc. The Development of affordable technologies, such as the Mini EV common platform (2012-2014).

Secure auto parts molding technology 1GPa-class ultra-high strength materials through an eco-friendly UHSS grade steel and lightweight components for automotive technology development (2011-2014) and development of Body Rails / Front Lower Control Arms.